In 2022 Clotho secured funding from S4Fashion which we used to initiate a new research phase called Circular Clotho, where we aimed make Clotho the first fully circular smart textile out there.

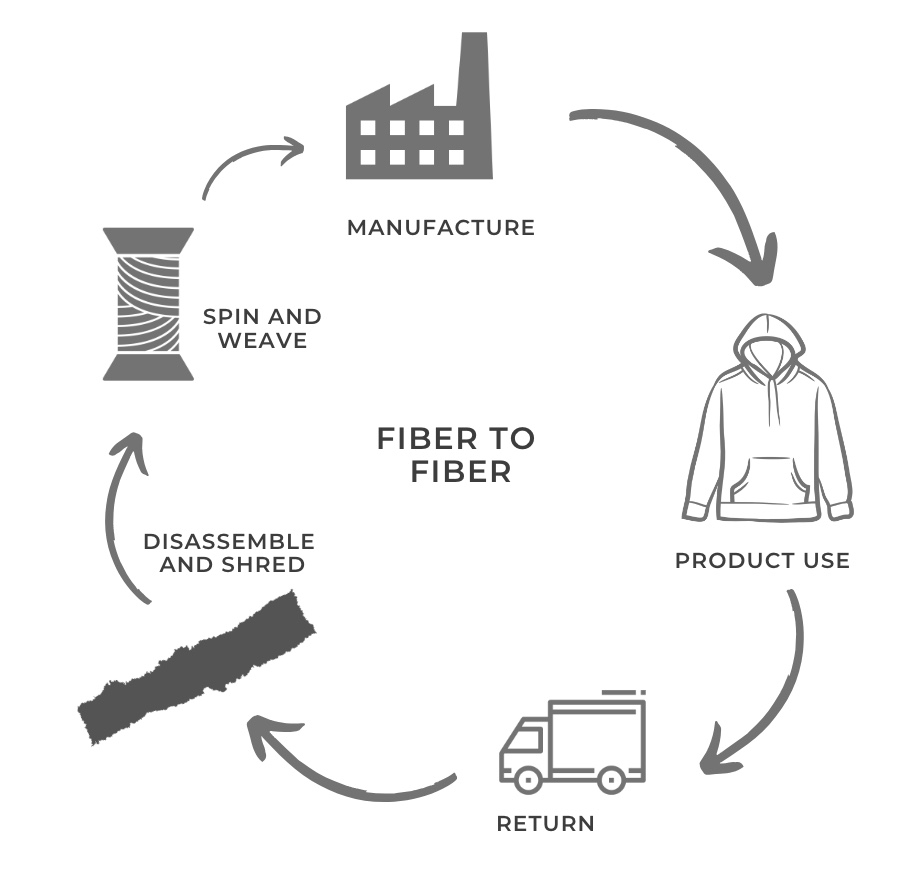

After months and months of research and trials, we finally managed to adopt a closed-loop solution, meaning that after spinning, weaving and manufacturing, a used and returned Clotho product can be disassembled and shred to become raw material that can be used for spinning and weaving again. Basically, no Clotho product will ever go to waste, as it can be repurposed in a circular manner.

Why is this such a huge and exciting achievement? This fiber-to-fiber process, where we essentially mechanically recycle pre- and post-consumer Clotho textile, is the first of its kind in the smart textile sector.

Why is this the sustainable way forward? The advantage of using mechanical recycling of cotton lies in its environmental impact. It does not use water or chemicals, it only needs small amount of energy, and it can be used for various cycles.

What does this mean for our consumers? It means that you can purchase something from Clotho confidently knowing that if you ever want to return something, the product will not be discarded but will instead be fully recycled and repurposed.

What does this mean for our clients? It means that integrating the Clotho textile in your offering supports you in your transition to a closed-loop approach, allowing your company to be one step closer to circularity and sustainability.

Achieving circularity was one of our main goals at the start of this journey, and we are so excited to see what else this year has got in store for us!

Get in touch if you want to add smart values to your collection!